Uh Oh. Something is missing. Try double checking things.

Steel grade: STEEL FOR QUENCHING AND TEMPERING

Steel for heat treatment is distinguished by a very wide range of steel grades with significantly different chemical compositions. It is ideal for use in areas subject to particularly high loads.

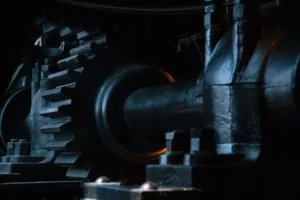

This type of steel is often used to manufacture parts such as axles, shafts, crankshafts, gears, levers, piston rods, grinding discs, and components subject to variable bending loads and fatigue. The carbon content in this family of steels ranges from 0.25-0.6%. One of the main alloying elements is chromium. Thanks to heat treatment, we can manipulate steel parameters such as strength, impact resistance, and ductility. Steel is heat treated for a specific task, and different sectors of the economy require different steel parameters. Some of the most important parameters are resistance to cracking, tensile strength, hardness, and fatigue resistance.

The heat-treated state T is obtained through hardening and high tempering. Tempering causes recrystallization of ferrite and spheroidization, followed by coagulation of carbides. This results in a structure called sorbite. To describe the heat treatment process of steel in a nutshell, it boils down to heating the material and tempering it. By repeating these cycles, we can achieve very interesting and satisfactory results. Two popular methods of heat treatment are tempering and hardening.

Steel for heat treatment – grades

40H, 40HM, 34HNM, 36HNM – these types of steel are intended for components where high strength is required

50HF and 50HS – these types of spring steel are most often used in the production of individual components of car parts such as gears or crankshafts, which are subjected to very high loads

30HGS, 35HGS – Pins, rollers, bushings, other heavily loaded components operating at a maximum temperature of 150-200 °C.