Uh Oh. Something is missing. Try double checking things.

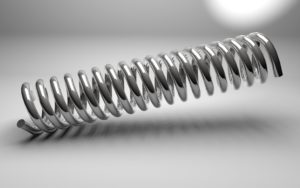

Steel grade: SPRING STEEL

What is spring steel?

Spring steel belongs to a separate group of alloy structural steels. As the name suggests, this type of steel is used in the production of springs, including springs in motor vehicles, spring washers, as well as leaf springs and torsion bars. Importantly, spring steels can be divided into two basic groups.

The first group consists of silicon steel, manganese steel, and silicon-manganese steel. Steels in this group are very elastic and undoubtedly have good plastic properties.

The second group consists of chromium steels, which contain vanadium, manganese, and silicon. Steels belonging to this group are more resistant to high temperatures than steels from the first group. It is also important to note that this is the main reason why steels of this type are used for the production of springs with larger cross-sections.

Steels belonging to this group are more resistant to high temperatures than steels from the first group. It is also important to note that this is the main reason why steels of this type are used for the production of springs with larger cross-sections.

Spring steel – properties

Spring steel has many important properties. It is worth mentioning here that these are:

elasticity

resistance to various types of damage – steel does not crack or deform

durability – it performs its function perfectly for many years

fatigue resistance – after the pressure exerted on it is removed, steel quickly regains its original shape

resistance to stress relaxation

ductility

impact strength

Spring steel processing

Of course, the processing process is extremely important here. A properly conducted process guarantees long life and resistance to deformation. The surface of the steel should be finished with great care and must be smooth and, above all, free of unevenness, scratches, or nicks. The smallest detail is of great importance here.

How is spring steel processed?

Spring steel is heated to a high temperature, usually 800-870°C. The next step is to harden the steel in water at a temperature of 30-40°C or in oil at a temperature of approx. 50-70°C. The final step is tempering, the temperature of which depends on the type of steel, but is usually between 300 and 520°C. For some types of steel, cooling is also recommended after tempering.

Strength and elasticity: Spring steel is known for its high strength and elasticity. It is these characteristics that make it widely used in various types of springs, such as car springs, clock springs, springs in tools, and many others.

Alloying: Spring steel is usually made of high-quality steel alloys that have been further strengthened by alloying. The addition of other elements, such as chromium, silicon, manganese, or vanadium, can significantly improve the properties of spring steel, such as corrosion resistance, strength, and elasticity.

Heat treatment: Spring steel requires proper heat treatment to achieve its elastic properties. This process involves hardening and tempering the steel at specific temperatures. Hardening ensures high hardness, while tempering reduces brittleness and provides greater flexibility.

Different types of spring steel: There are many different types of spring steel, each with its own unique properties. For example, carbon steel (also called spring steel) is a popular choice due to its strength and low cost. There are also spring steel alloys, such as stainless steel, chromium-silicon steel, and tungsten steel, which offer special properties depending on the application.

Applications in various industries: Spring steel is widely used in many industries. In addition to springs, it is used in the manufacture of tools, automotive suspension components, clock and watch parts, medical equipment, industrial machinery, and many others.

Research and innovation: Research on spring steel is still ongoing in order to improve its properties and adapt it to the specific needs of various fields. Engineers and scientists are constantly looking for new alloys and heat treatment techniques to achieve even better properties in spring steel.